Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

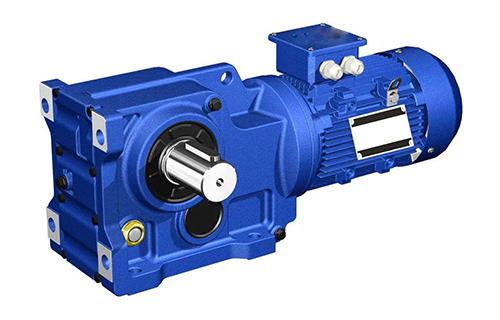

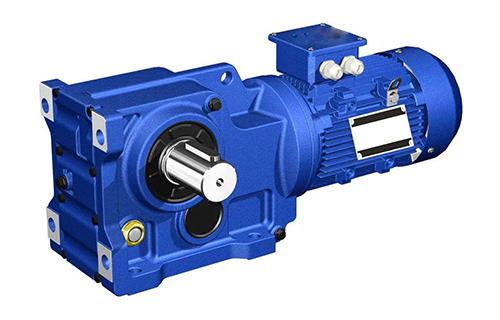

Hard tooth surface reduction motor

Hard tooth surface reducer is a precision mechanical device that reduces speed and increases torque through high-strength gear transmission. It has advantages such as high load-bearing capacity, low noise, and long service life, and is widely used in the field of industrial transmission. The following is the compilation of its core information:

1、 Definition and Core Features

Hard tooth surface reducers use processes such as carburizing, quenching, and grinding to significantly increase the hardness of the gear surface (usually ≥ HRC58), thereby possessing the following characteristics:

High performance: High load-bearing capacity (2-3 times higher than soft tooth surface reducers), transmission efficiency of over 96%, low noise (optimized design to reduce meshing impact).

Long service life: The gears are made of high-strength low-carbon alloy steel (such as 20CrMnTi), which has been carburized, quenched and precision ground, with strong wear resistance. The service life is 2-3 times longer than that of soft tooth surface reducers.

Compact structure: small in size and light in weight, saving more than 30% space compared to traditional reducers under the same power.

2、 Application Fields

Widely applicable to scenarios that require high torque and harsh working conditions:

Heavy industry: metallurgy, mining, cement, chemical industry, lifting and transportation (such as belt conveyors, scrapers).

General machinery: textiles, printing and dyeing, pharmaceuticals, fans, water pumps, etc.

Precision equipment: servo/stepper transmission systems, robots, automated production lines (planetary hard tooth surface reducers).

3、 Structure and Working Principle

Transmission structure:

Multi stage gear transmission: usually 2-3 stages, the first stage uses Gleason spiral bevel gears (for steering), and the subsequent stages are involute helical cylindrical gears (to reduce noise and improve coincidence).

Modular design: supports multiple assembly types (such as horizontal, vertical, hollow shaft), adapting to different installation environments.

working principle:

Reduce speed through gear ratio (such as driving a large gear with a small gear), while amplifying torque. Output speed=input speed/transmission ratio, output torque=input torque x transmission ratio x efficiency.

Lubrication method: oil pool splash lubrication (conventional) or cyclic lubrication (high load/high temperature scenario).

4、 Model and Parameters

Taking the common DBY/DCY series as an example:

Model composition: composed of type code, center distance, transmission ratio, assembly type, and rotation direction.

Example: DCY 560 31.5 Ⅱ N

DCY: Three stage hard toothed reducer for belt conveyors;

560: The center distance of the final stage is 560mm;

31.5: nominal transmission ratio;

II: Assembly type;

N: The input shaft rotates counterclockwise.

Parameter Range:

Center distance: 160-800mm (different series specifications vary);

Transmission ratio: 8-50 (multiple gears available), supporting clockwise/counterclockwise rotation.

5、 Materials and processes

Material: The gear is made of low-carbon alloy steel such as 20CrMnTi, with a tooth surface hardness of HRC58-62; The shell is made of high-strength cast iron (such as FC-25) or cast steel to ensure rigidity.

Key processes: carburizing and quenching (to improve tooth surface hardness) → grinding teeth (with an accuracy of ISO 6-7) → non-destructive testing (to ensure no defects).

6、 Selection and maintenance suggestions

Key selection points:

Select the model based on load torque, speed, installation space, and environment (such as temperature and dust), and pay attention to thermal power limitations (cooling measures are required if exceeded).

Installation and maintenance:

Ensure that the input and output shafts are aligned and avoid hitting the output shaft (to prevent breakage);

Regularly check the oil level and quality, and recommend using medium load gear oil (such as ISO VG220).

summarize

Hard tooth surface reducers, with their high reliability and excellent transmission performance, have become the core components of industrial transmissions, especially suitable for heavy-duty and high-precision scenarios. When selecting, specific operating parameters should be considered to ensure standardized installation and maintenance, in order to maximize equipment lifespan and efficiency.

Comments (2)

Rasel ArnoldJan 24, 2024

Though author order shouldn't matter, industry custom and practical limitations say otherwise.

Ryans JosephJan 22, 2024

Though author order shouldn't matter, industry custom and practical limitations say otherwise.